HIGH-QUALITY MOLDING IS OUR STANDARD.

Leveraging the most skilled operators in the industry, our company strives to produce the best parts possible, at a competitive price, from a singular piece to hundreds of thousands of pieces.

OUR SERVICES

We have been providing quality solutions for plastic injection molds since 1990. By investing in the newest technology, establishing process development and investing in our employees has enabled us to provide innovative tooling solutions for our customers. However, our greatest strength as a company is our staff that is focused on ensuring that all of our customers’ needs are a priority and that every customer need meets the highest of standards.

MOLD TESTING

PROGRAM MANAGEMENT

MANUFACTURING

QUALITY ASSURANCE

OUR MACHINE INFO

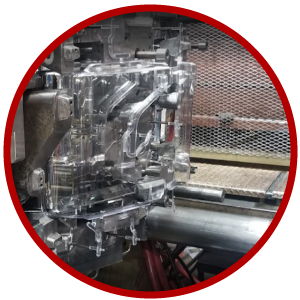

Injection Technologies offers 20 injection molding machines, ranging in size from 100 ton to 3500 ton, including two 1800 multi-shot rotary presses. We are specialists in mold try-outs. We have the best set-up and machine operators in the business.

Our molding machines were all sourced with a focus of flexibility to support as many tools as possible and to facilitate quick mold changeovers. Presses are all fitted with hot runner controllers with SVG manifolds, thermolators (regular and high heat), and dryers.

Injection Technologies has 8 cranes ranging from 10 ton to 50 tons capacity, as well as a loading dock and multiple overhead doors.

This facility also offers private offices and multiple full sized conference rooms for its customers to utilize. In addition, the building is outfitted with fiber optic internet and a complimentary customer lounge.

With our customers in mind, we offer:

- 1800 Ton 3 shot with a piggyback + side injection configuration

- 1800 Ton 4 shot with 3 parallel barrels + side injection

- Robotic part extraction

- Second barrel add-on to our 2200 ton to simulate two shot molding

- 550 ton with an 18 oz shot to support PC, ABS and Nylon parts

- Gas assist and gas counter pressure

- An afternoon shift leader with 30 years of experience and a second operator on afternoons to allow customers flexibility to troubleshoot and run quantities late into the evening, try-outs can start up until 10:00pm

MASS PRODUCTION READY

CUSTOMER SERVICE

MOLD TESTING

ENGINEERING SERVICES

WE OFFER

FIRST CLASS

SERVICE

“Great Molding Trial Shop with great people and awesome personalities.”

-S. Price

OUR COMPANY

Injection Technologies, which first opened in 1990 as the area’s “original” mold testing facility and today operates as a full-service molding operation.

Leveraging the most skilled operators in the industry, the company strives to produce the best parts possible, at a competitive price, from a singular piece to hundreds of thousands of pieces.

Our leaders each have over 25 years of processing experience with our operators averaging 15 years of plastic injection molding. Injection Technologies Inc. is certified ISO 9001:2015.

OUR CAPABILITIES

In its 48,000 sq. ft. facility, Injection Technologies operates 16 injection molding presses with capacity ranging from 140 tons up to 3500 tons, while an additional 16,000 sq ft. in offsite warehousing enables the company to house large quantities of resin, parts and packaging. The company’s molding machines were all sourced with a focus of flexibility to support as many tools as possible and to facilitate quick mold changeovers. Presses are all fitted with: hot runner controllers with SVG manifolds, thermolators (regular and high heat), and dryers.

The above qualities and more will ensure our company’s success in achieving its goal to “efficiently produce the best part possible.”

BOOK A MEETING WITH US

Our qualities and more will ensure our company’s success in achieving its goal to “efficiently produce the best part possible” for our customers.